Dielectric Materials

Introduction

Dielectric materials, which store energy electrostatically, are ubiquitous in advanced electronics and electric power systems. Generally speaking, the dielectric materials have poor electrical conductivity, and by spacing the electrodes in such a way that the electrodes maintain opposite charges while forming an electric field. Depending on the application, the performance requirements of the dielectric materials are also different. The bulk ceramics, polymers and polymer nanocomposites are the focus of the dielectric materials.

Types of dielectric Materials

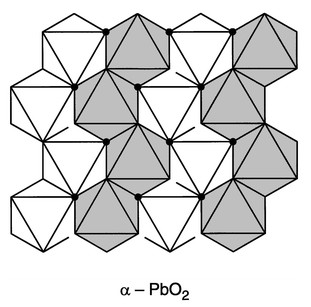

In parallel with the advancements in electronic Components, significant developments have been made in ceramics dielectric materials, which can be categorized into several groups, namely (Zr1-xSnx)TiO4-zirconium tin titanate,Ba(Zn1/3Ta2/3)O3 and related perovskites,Barium titanates: Ba2Ti9O20, BaTi4O9, and Ba-Ln-Ti-O, Ca5TiNb2O12 perovskites, Ca2Ta2O7-Ca2Nb2O7 pyrochlores, BST-BSN and Ta2O5-Al2O3. For example, (Zr1−xSnx)TiO4-zirconium tin titanate is widely used in microwave devices. The basic compound, ZrTiO4, has a relatively low temperature coefficient of the dielectric constant, but has been found to have optimal properties. It’s crystal structure is of the α-PbO2 type, shown in Fig. 1, based on columns of zigzag chains of edge shared metal–oxygen octahedra, two octahedra wide. These columns share corner oxygens with columns in the next metal plane in a close-packed oxygen lattice.

Fig.1 The crystal structure of ZrTiO4, the α-PbO2 type[1].

Fig.1 The crystal structure of ZrTiO4, the α-PbO2 type[1].

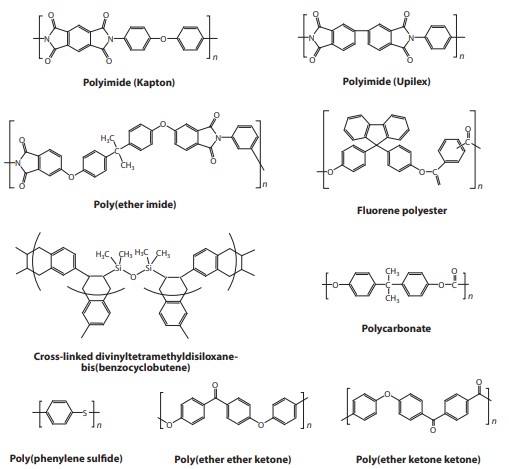

In the area of high temperature dielectric materials, the advantages of polymer dielectrics for capacitor applications have been well documented and include high breakdown strength, low mass density, inexpensive production, flexibility, and ease of processing. As shown in Fig. 2, the chemical structures of some of the most promising and commercially valuable current state-of-the-art high-temperature polymer dielectrics are listed. Polymer nanocomposites can also maintain stable properties at high temperatures.

Fig.2 Chemical structures of various high-temperature polymer dielectrics[2].

Fig.2 Chemical structures of various high-temperature polymer dielectrics[2].

The polymer composite approach to dielectric materials combines the unique thermal, mechanical, and electrical properties of inorganic inclusions with the facile processability and high breakdown strength of polymeric matrices for improved dielectric properties and capacitive energy storage performance, which mainly includes single-layer composites and sandwich-structured composites. Inorganic doping is often used to enhance the performance of polymer composite, thereby enabling them to perform in higher intensity condition.

Application

Dielectric materials form one of the most fundamental passive components known as film capacitors, which are present in almost every sort of electronic circuit. The function of film capacitors is to store electric energy by holding opposite charges on electrodes separated by an insulator, the dielectric material. Dielectric capacitors are special among the various electrical energy storage devices, batteries, because they can release the stored energy in an extremely short period of time (on a microsecond scale) to create intense power pulses. This capacity enables many pulsed power applications such as medical defibrillators, transversely excited atmospheric lasers, and advanced electromagnetic systems, in which capacitors convert a low-power, long-time input into a high-power, short-time output. Lately, emerging products related to renewable energy, such as hybrid electric vehicles, grid-tied photovoltaics, and wind turbine generators, have created a great demand for dielectric capacitors, as they are vital electronic elements for the conversion of collected/stored direct current to alternating current energy.

References

- CAVA, R. J. Dielectric materials for applications in microwave communications. Journal of Materials Chemistry, 2001, 11.1: 54-62.

- LI, Qi, et al. High-temperature dielectric materials for electrical energy storage. Annual Review of Materials Research, 2018, 48: 219-243.

![5,10-Dihydroindeno[2,1-a]indene](https://resource.bocsci.com/structure/6543-29-9.gif)

![Bicyclo[3.3.0]octane-2,4,6,8-tetracarboxylicdianhydride](https://resource.bocsci.com/structure/4945-72-6.gif)